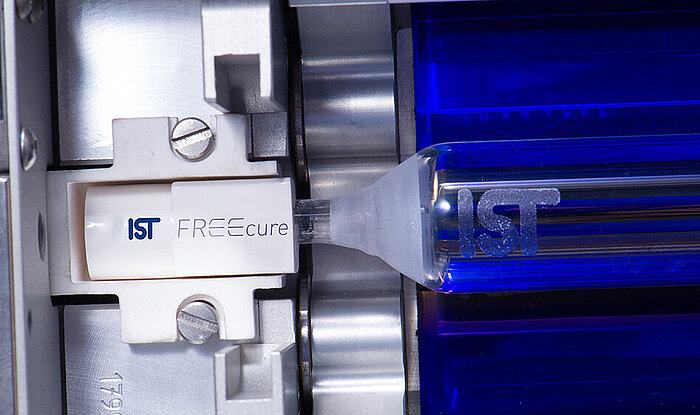

FREEcure – a new way to use UV light

Environmentally friendly curing solutions are essential in industrial wood processing. UV curing of inks and varnishes is a proven, fast, and energy-efficient method.

Traditionally, photoinitiators are added to UV varnishes and UV inks to absorb the UV light, generate radicals and thus start the curing process by converting the C=C double bond.

The efficiency of the UV curing process is significantly impaired at the surface by oxygen inhibition (the termination reaction of chain formation via oxygen), which in turn can lead to a reduction in production speed and even limited surface properties. The known technical solutions for these problems are the inertisation of the irradiation space or the excessive addition of photoinitiators. However, this leads to further technical challenges with regard to yellowing, odour and migration, which make use in sensitive areas of application, such as kitchen surfaces, more difficult.

Due to supply bottlenecks, increased regular requirements and the elimination of some photoinitiators, the question arose as to whether it would be possible to realise the UV polymerisation process without or with a significantly reduced photoinitiator content and at the same time prevent oxygen inhibition. An inert environment should be deliberately avoided.

Even before the discussions about sustainability, rising energy prices and reducing the CO2 footprint, our UV experts have been working on minimizing the environmental impact of IST UV curing systems and researching innovative approaches to meet the increased customer demand for sustainable trends. Together with UV experts from BASF, our UV specialists have developed the FREEcure system, which will play an increasingly important role in wood processing technology and has what it takes to reduce energy consumption.

This is made possible by a UV curing process that is achieved by direct cross-linking of the C=C double bond.

In order to split such compounds directly, however, a certain amount of light energy is required that is above the binding energy of the C=C double bond.

As UV light is all the more energetic the shorter the wavelength, the light spectrum of the UV system had to be shifted into the short-wave UVC range and this range had to be additionally amplified.

After careful consideration and examination of different UV light sources, it became clear that the UV medium-pressure mercury lamp offers the best conditions for this process. Therefore, based on our proven IST-UV system BLK and in combination with a UV medium-pressure mercury lamp, a system was developed that can generate a power increase of more than 70% in the UVC spectral range and also disproportionately increases wavelengths below 220 nm.

The main measures in this regard were:

- Adaptation and optimisation of the plasma technology inside the UV lamp

- Use of special materials in the area of UV lamps, reflectors and pass filters

- Optimisation of the electronic control

Comprehensive binder screenings have shown that FREEcure is suitable for both 100% systems and aqueous systems. Comprehensive expertise can now be drawn on. The following aspects play a role here:

- No photoinitiator

- Chemical composition/functionality of the binder

- Amine modification for effective suppression of oxygen inhibition

- Physical surface drying of aqueous UV dispersions.

To summarise, according to BASF experts, it can be confirmed that

- Waterborne and 100% UV binders can be cured efficiently with FREEcure.

- Additional use of photoinitiators in waterborne clearcoat systems is not necessary, while in 100% systems they can be reduced to a minimum (<<0.5%)

- High double bond conversions (>80%) are possible in coatings

- High chemical resistance can be achieved, comparable to classic systems using industry-standard amounts of photoinitiator

- Special requirements are placed on the binder in order to guarantee optimum performance of the coating.

This helps the formulator to overcome hurdles resulting from various regulatory requirements for the composition and processing of their products.

The application decides

In some applications, the reduction/elimination of photoinitiators takes centre stage.

It was possible to cure sprayable UV water-based coatings in different colours (blue, yellow, black, red, white) as well as UV primers on melamine film without photoinitiators while maintaining the full property profile.

With 100% UV systems that are used on high-speed roller coating lines in the furniture industry, it can make sense to add a certain proportion of photoinitiators (approx. 1/4 to 1/3 of the original quantity) in order to achieve the desired production speed with as few UV units as possible. The energy efficiency argument takes centre stage here. Speeds per FREEcure unit in the range of 30-50 m/min are conceivable here. This means that a maximum of 2-3 FREEcure units are required, even for high-speed roller coating lines. Depending on the application, it is conceivable to combine the FREEcure units with UV LED systems in order to cure large layer thicknesses, even in depth.

The statements made above are also confirmed in the printing sector. This is particularly the case in the printing and coating of food packaging. Here we have experience with offset and flexo inks that can be cured photoinitiator-free up to 200 m/min.

The advantages at a glance:

- Energy efficiency: The high efficiency of the FREEcure system leads to extremely short curing times and significant energy savings, which also reduce the CO2 footprint

- Environmental friendliness: By eliminating or reducing the use of photoinitiators, the odour and migration potential of coatings is reduced

- Cost efficiency: Reduced operating costs due to a lower number of UV units, lower space requirements and lower spare parts costs, as well as lower energy consumption, lead to a cost-efficient production process

Summary

The FREEcure process therefore offers a completely new approach to using UV light, as it minimises the use of photoinitiators or even eliminates them altogether thanks to an extremely high proportion of UVC light. This is particularly important and of great benefit in the production of sensitive products using low-migration inks and coatings. The extremely powerful system promotes energy savings - because by using FREEcure, the number of UV dryers can be reduced in many cases and space-saving potential generated. In concrete terms, this means possible energy savings of up to 75% and therefore in the 6-digit euro range, several hundred tonnes of CO2 savings depending on the production site, a significantly smaller footprint and amortisation times of 1.5 to 2.5 years. Lower spare parts costs can also be expected in the long term. In the long term, the combination of LED UV for all bottom layers and FREEcure for the top coat in the wood area is a step in the right direction to realise the balancing act between the greatest possible environmental friendliness and high-performance coatings at the same time.

Testimonial: Dr. Christian Gerhard Schäfer, BASF SE

The FREEcure system is an excellent example of how co-operation between BASF and IST METZ can produce an innovative solution for the curing of paints and varnishes. The basic prerequisite for this was the targeted harmonisation of raw material and lamp technology, which enabled us to develop optimal product solutions and also to bring the process from the raw material side to series production readiness. This is particularly relevant for applications such as the printing and coating of food packaging and the finishing of wood, metal and plastic surfaces. We are proud to have supported the development of this system and are convinced that it will play an important role in promoting environmentally friendly curing solutions.