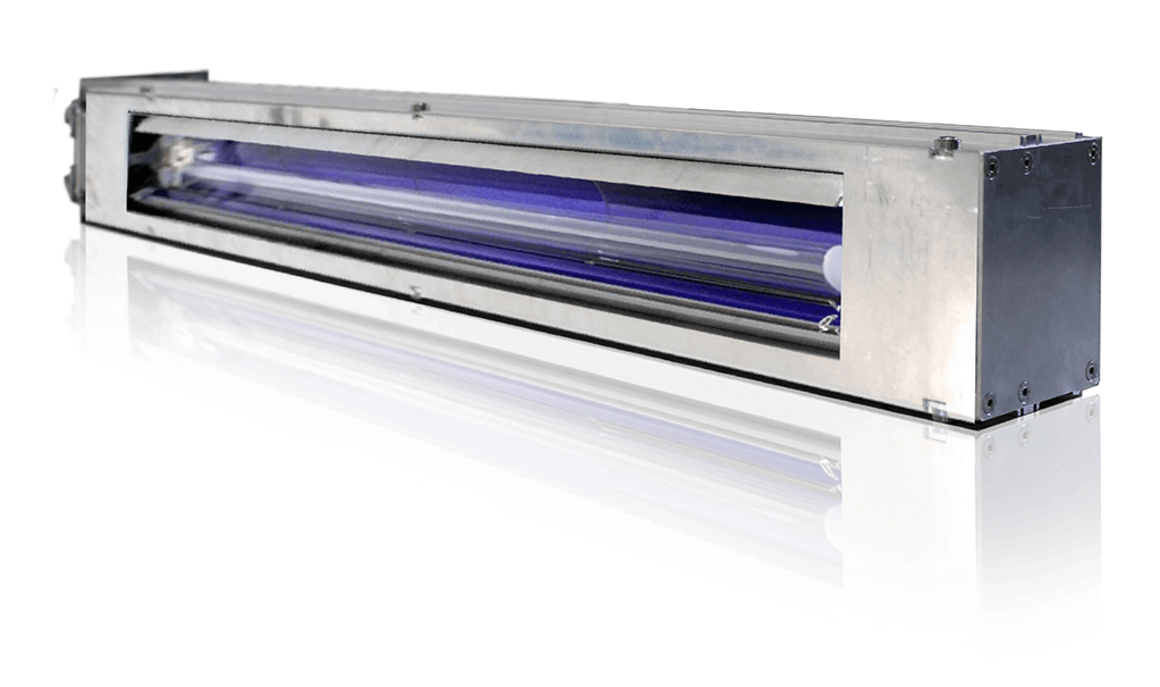

The FREEcure UV system revolutionises UV curing with an innovative solution that opens up completely new possibilities. Thanks to an extremely high UVC content, our patented FREEcure system minimises the use of photoinitiators - or even makes them superfluous. FREEcure is our answer to the requirements of the new printing ink regulation.

Efficient, sustainable and low-migration UV curing

The FREEcure system enables a completely new type of UV curing - photoinitiator-free. This minimises the migration of potentially undesirable substances and is therefore ideal for applications in packaging printing, especially for food. FREEcure ensures maximum safety and quality, especially when producing with low-migration inks for sensitive products and packaging.

Thanks to the high-energy UVC light, which is exclusively available on the market, the FREEcure system breaks double bonds directly - without the use of photoinitiators. The innovative technology also significantly reduces the number of lamps required for dose-intensive applications, which increases efficiency and reduces costs. FREEcure sets new standards in UV curing and paves the way for greater efficiency and sustainability.

Based on our tried-and-tested BLK system, we have developed FREEcure - a powerful solution that combines innovation, sustainability and efficiency. In combination with a UV medium-pressure vapor lamp, it enables an increase in output of over 70 % in the UVC spectral range and also raises wavelengths below 220 nm disproportionately. FREEcure therefore not only optimizes UV curing results, but also reduces energy consumption at the same time.

In many applications, particularly in the wood industry, FREEcure enables a significant reduction in the number of dryers required - with savings of up to 75% in energy and several tons of CO₂ per year. The system also impresses with its smaller footprint and short amortization times of just 1.5 to 2.5 years. Thanks to its low photoinitiator content, FREEcure is also becoming increasingly important in other areas of UV curing.

Discover the advantages of FREEcure and set new standards in your production with this innovative technology!

FREEcure uses the innovative technology of UV direct crosslinking to take curing processes to a new level. With its unique combination of photoinitiator-free processes, low-migration results and environmentally friendly curing technology, FREEcure is setting new standards in the industry. By dispensing with chemical additives such as photoinitiators, a new era of UV curing is being ushered in that combines safety, sustainability and efficiency. This is also reflected in the following advantages:

The demand for environmentally friendly curing solutions in wood processing is constantly increasing. UV curing of paints and varnishes is a proven, fast and energy-efficient technology that reduces emissions and enables particularly scratch-resistant surfaces.

Long before the current discussions about sustainability, rising energy prices and reducing the carbon footprint, our UV experts were already working on minimizing the environmental impact of our UV curing systems. They are continuously developing innovative solutions to meet the increasing demand for sustainable technologies. In collaboration with BASF, the FREEcure system was developed, which is playing an increasingly important role in wood processing and can significantly reduce energy consumption.

For 100% UV systems in high-speed rolling mills in the furniture industry, it can make sense to reduce the photoinitiator content (approx. 1/4 to 1/3 of the original quantity) in order to achieve the desired production speed with as few UV units as possible. The focus here is on energy efficiency. With our FREEcure system, speeds of 30-50 m/min per unit can be achieved, so that only 2-3 units are required for high-speed rolling mills. In some applications, the combination with LED UV systems can be useful in order to cure even thick layers efficiently.

Choose future-proof UV technology - for sustainable, efficient and economical production processes in the wood industry.