Special applications need adhesives with specifically defined properties. It is possible to adjust the adhesive properties of UV acrylates depending on the amount of UV exposure after application. With increased UV exposure the layer of glue becomes less adhesive. This results from the effect of UV exposure on acrylate adhesives.

The amount of UV exposure is controlled by the specifications of the UV lamps used and the production speed of the machine. Therefore, a whole range of adhesives with different properties can be produced from one basic adhesive and varying UV exposure.

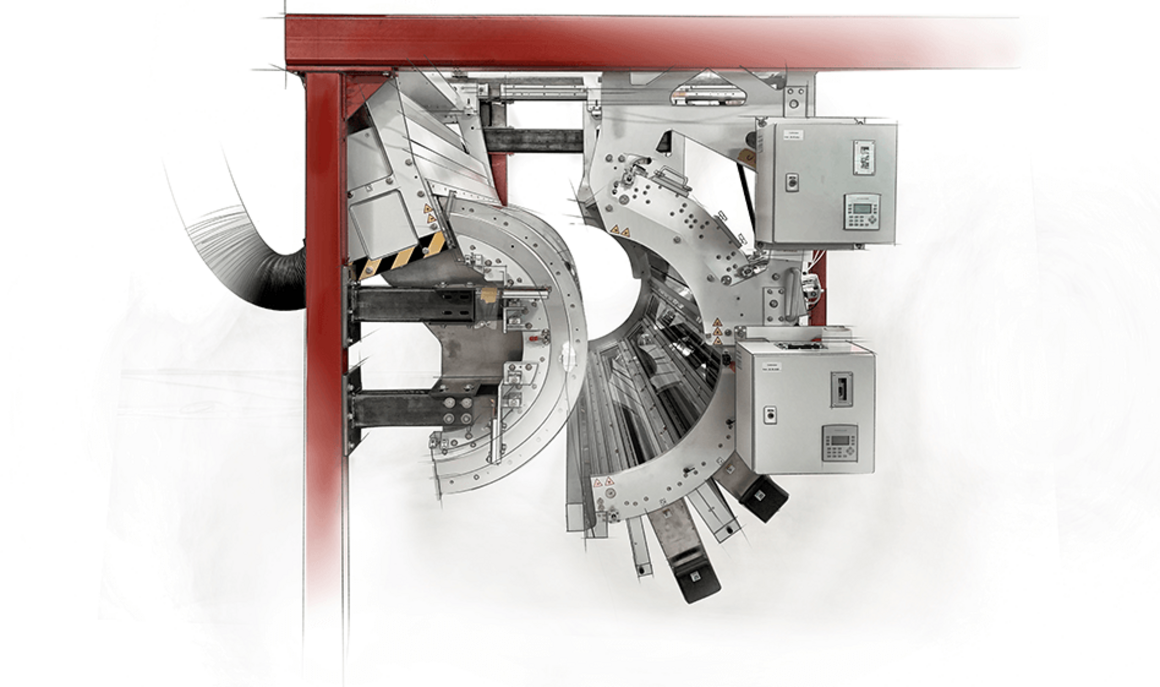

After the adhesive has been applied, the coated web is passed through UV lamps that activate the cross-linking process. UVC sensors ensure precise adjustment and monitoring of the UV dose, while the continuously variable ELC power control ensures constant dosing. This guarantees that the exact UV dose is always applied to the adhesive film to produce a product with consistent properties.

Hotmelt/PSA is used in various areas, including label production, adhesive tapes, the automotive supply industry and specialised applications. In all of these applications, precise and constant UV dosing ensures reliable and consistent product quality, optimising industrial processes and meeting the highest standards of precision and performance.

UV acrylates offer a high level of ecological safety and enable fast production, even with large application quantities. They are characterised by excellent maturing behaviour and outstanding resistance to heat and moisture. They can also be easily processed with standard hotmelt coating systems, which guarantees easy handling and efficient use in various applications.

UV hotmelts offer numerous advantages: they are characterised by high heat stability when labels and tapes are applied at higher temperatures. They also remain resistant to UV radiation and oxygen, which prevents embrittlement and yellowing. Their moisture resistance makes them ideal for use in humid environments. Compared to SIS hotmelts, they allow a lower processing temperature. They also contain no solvents, which makes them ecologically and toxicologically safe. Finally, they offer flexible application for different types of glue thanks to a variable degree of curing.