UV curing for metal

Efficient, durable and sustainable surface finishing

By using UV curing, coatings can be cured in a matter of seconds, which significantly speeds up production processes and improves surface quality at the same time. UV curing also ensures reliable and environmentally friendly curing of both solvent-based and solvent-free UV coatings. These effectively protect metal surfaces against corrosion, abrasion and chemical influences and ensure a resistant, high-quality coating.

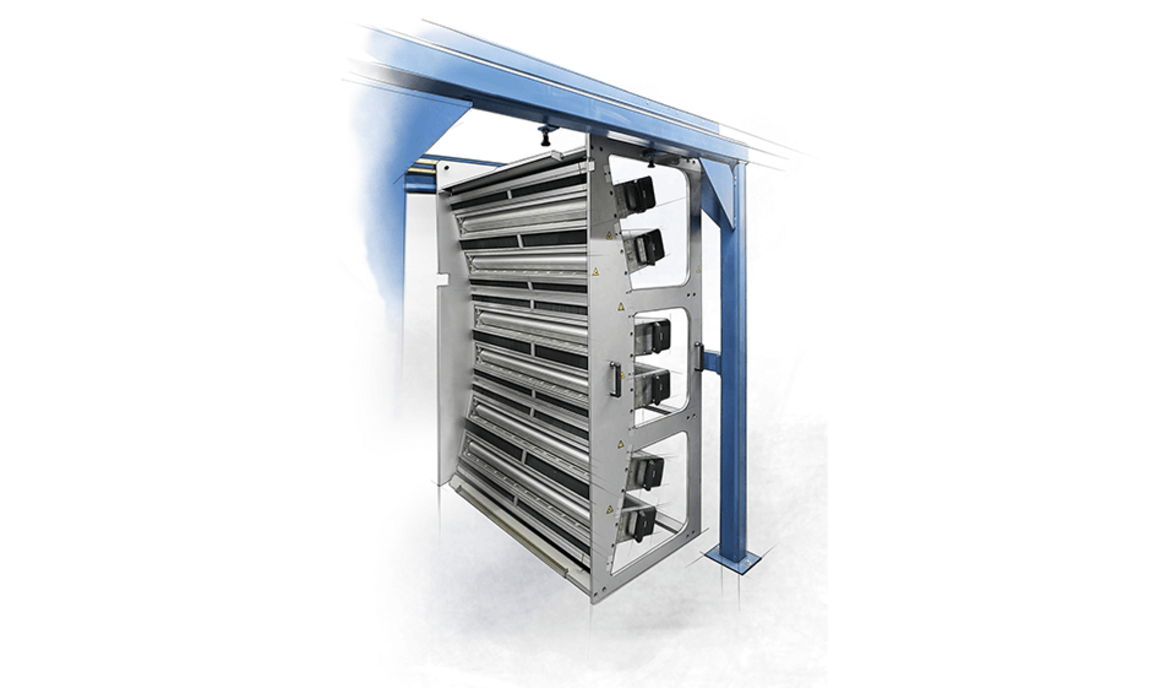

Our air-cooled UV systems offer an efficient solution for coating and curing metal, even for complex components and geometries, such as those frequently found in the automotive industry. The fast curing of the coating layer not only optimises the production process, but also ensures a uniform, durable and highly resistant coating.

UV curing is used in numerous industrial applications, especially for metal components that have to fulfil the highest requirements in terms of durability and quality. Our UV systems are suitable for a wide range of metal substrates and are used in various industrial sectors. Typical application examples are

UV curing not only ensures a high-quality surface finish, but also increases the efficiency and sustainability of the entire production process. Compared to conventional drying and curing processes, coatings cure within seconds, which enables shorter production times and higher throughput rates. This results in extremely durable surfaces that are optimally protected against mechanical stress, chemicals and the effects of the weather. UV curing also requires significantly less energy than thermal processes and therefore helps to reduce CO₂ emissions. Thanks to the precise control, uniform and targeted curing is guaranteed - even with complex component geometries.