Reflectors

Suitable for all applications

Reflectors are very important elements of a UV curing system, as 60% of the rays that hit the substrate come from reflectors. The geometric shape and reflectance of the reflectors are major characteristics that ensure the performance of your application. Our reflectors are made up of an assembly of 70 thin layers of metal deposited under vacuum to optimise their reflection.

Depending on the thermal sensitivity of the substrates to be treated, UV systems are equipped with reflectors that absorb IR emissions or not. URS reflectors have ‘Cold Mirror’ technology because they will transmit a minimum of IR onto your substrate, whereas URS-A reflectors are optimised to transmit a maximum of heat as well as UV.

The new generation of cold mirror reflectors, URS reflectors, provides considerable benefits in terms of increased efficiency as well as increased UV energy reaching the substrate. Higher output, lower energy consumption! Trials have been carried out with the new reflectors both in the laboratory and in practical field tests in the offset, flexo, screen printing and letterpress sectors. The UV measurements taken during these show that comparable UV curing results are possible with reduced energy consumption.

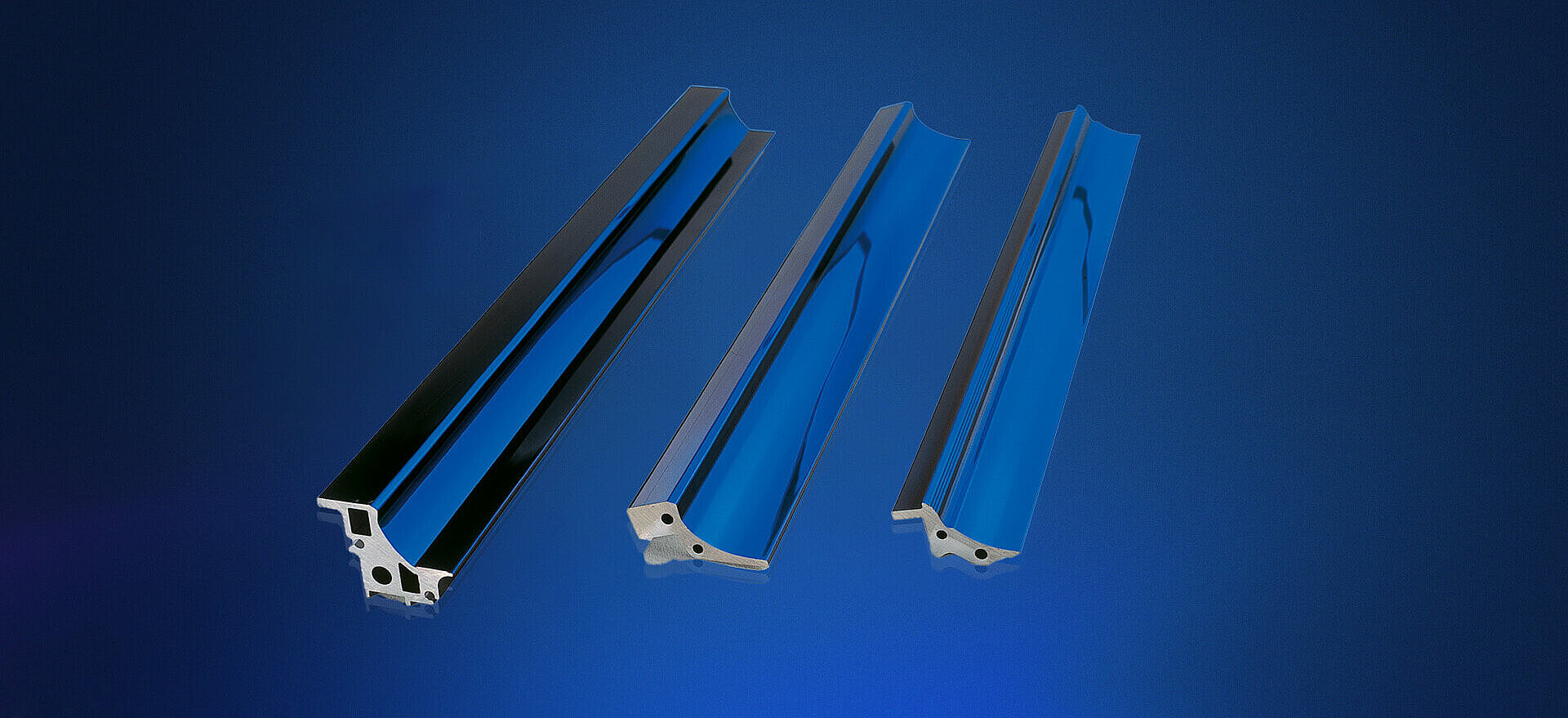

The new URS cold mirror reflector technology combines the advantages of the well-established aluminium and CMK (cold mirror) reflectors: only the UV light is reflected whilst the IR energy (heat) passes through the dichroic coatings and the cold mirror glass into a water-cooled absorber profile where the heat is efficiently removed. In addition, additional reflector profiles increase the UV energy reaching the substrate.

Benefits

URS A reflectors have been specially developed for applications in which targeted heat is heat is applied to the coating or printing substrate to favour the curing of inks and coatings. curing of inks and varnishes.

Measurement results and practical use have shown that the energy consumption can be significantly reduced compared to conventional aluminium reflectors. aluminium reflectors. The reason for this is an optimised degree of reflection in the UV range.

Design principle

The basis is a water- or air-cooled aluminium profile, which is vapour-deposited in a high vacuum with approx. 60 wafer-thin metal oxide layers. vapour-deposited. The aim is to maximise UV power to the substrate surface. The layer system allows a targeted addition of the infrared component of the radiation. Depending on the production process different reflector geometries are used.

Compared to URS, URS A reflector technology is characterised by an increased heat input onto the substrate.