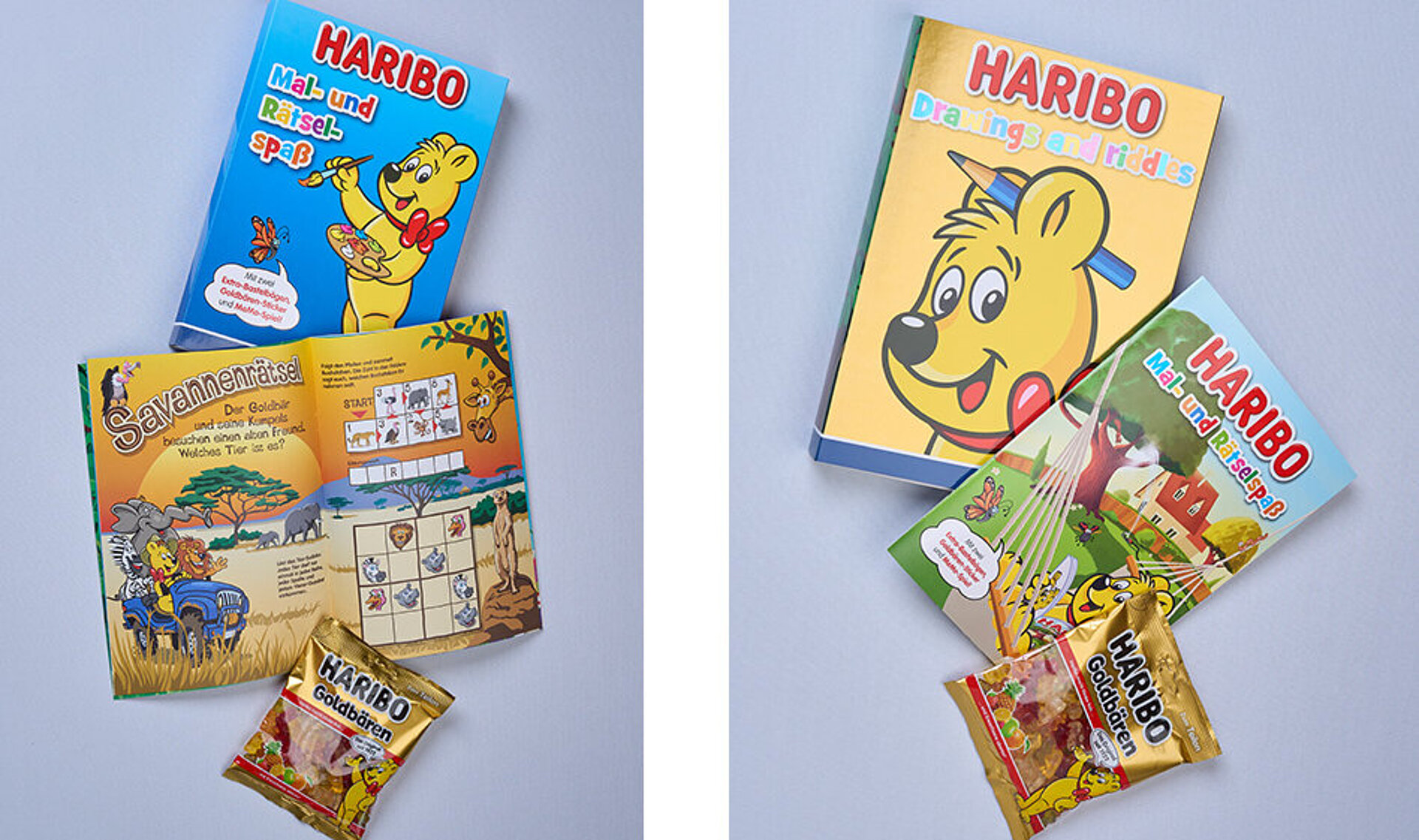

The print job for Haribo using the Heidelberg Speedmaster CX 104, we demonstrated how versatile a printing process can be. We presented a multi-colour, highly finished packaging print with impressive coating effects as well as a classic 4c commercial print, which is hardened with the latest LED UV technology for immediate further processing. The centrepiece of these demonstrations was the print job for the German brand Haribo, for which the LED UV ink Saphira was used.

The waterproof cooler demonstrates that waterproof folding carton packaging can be produced without the use of plastic, plastic coatings or films thanks to the intelligent interplay of design, substrate and coatings.

In addition, the intelligent use of effect coatings also enhances the look and feel of functional packaging.

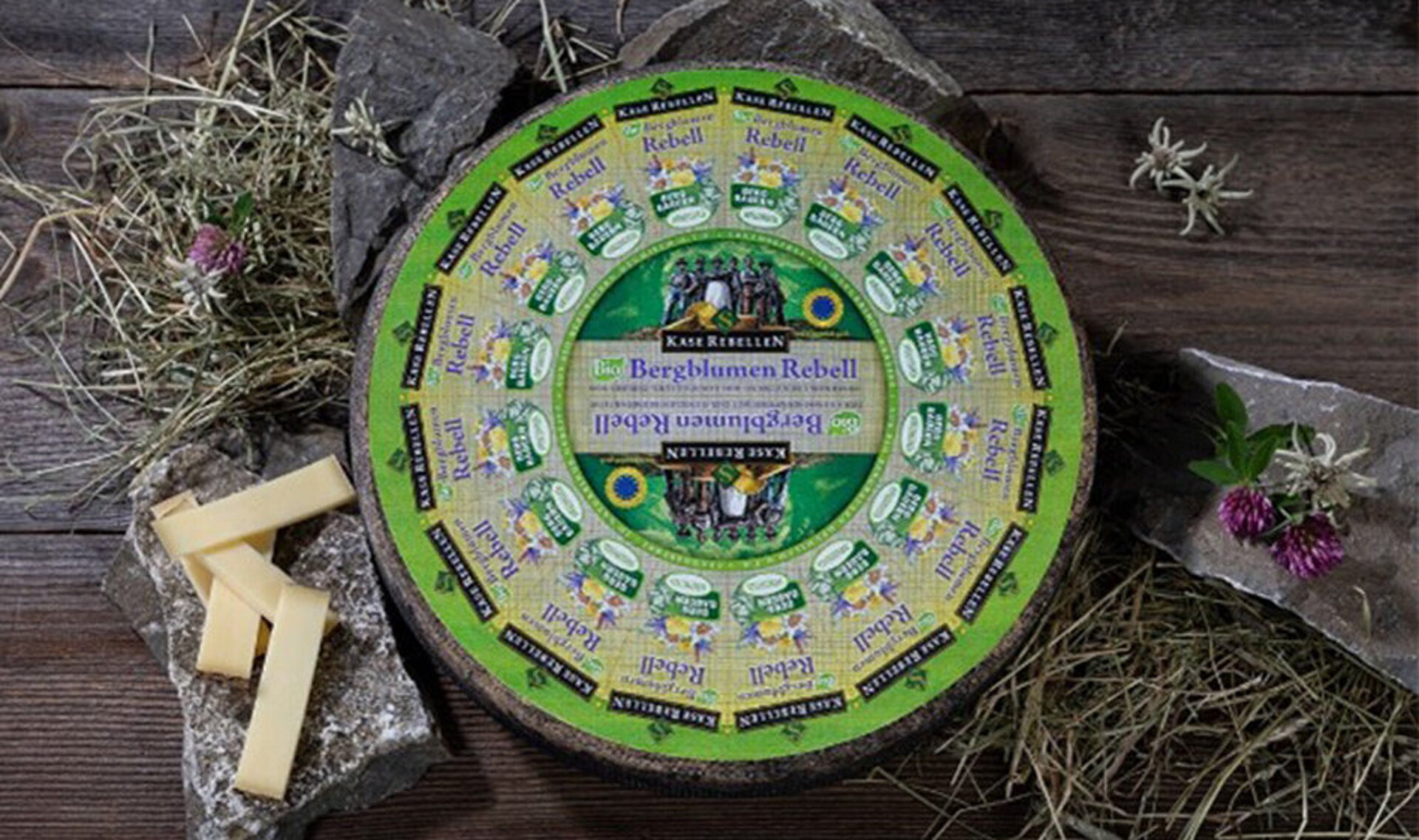

IST UV technology is also used for label printing, such as the labels used by Käserebellen for their Bergblumen Rebell.

Here, opaque white was applied in the first unit of the printing press, which was dried with the help of an intermediate dryer. The labels are also die-cut inline in the coating unit.

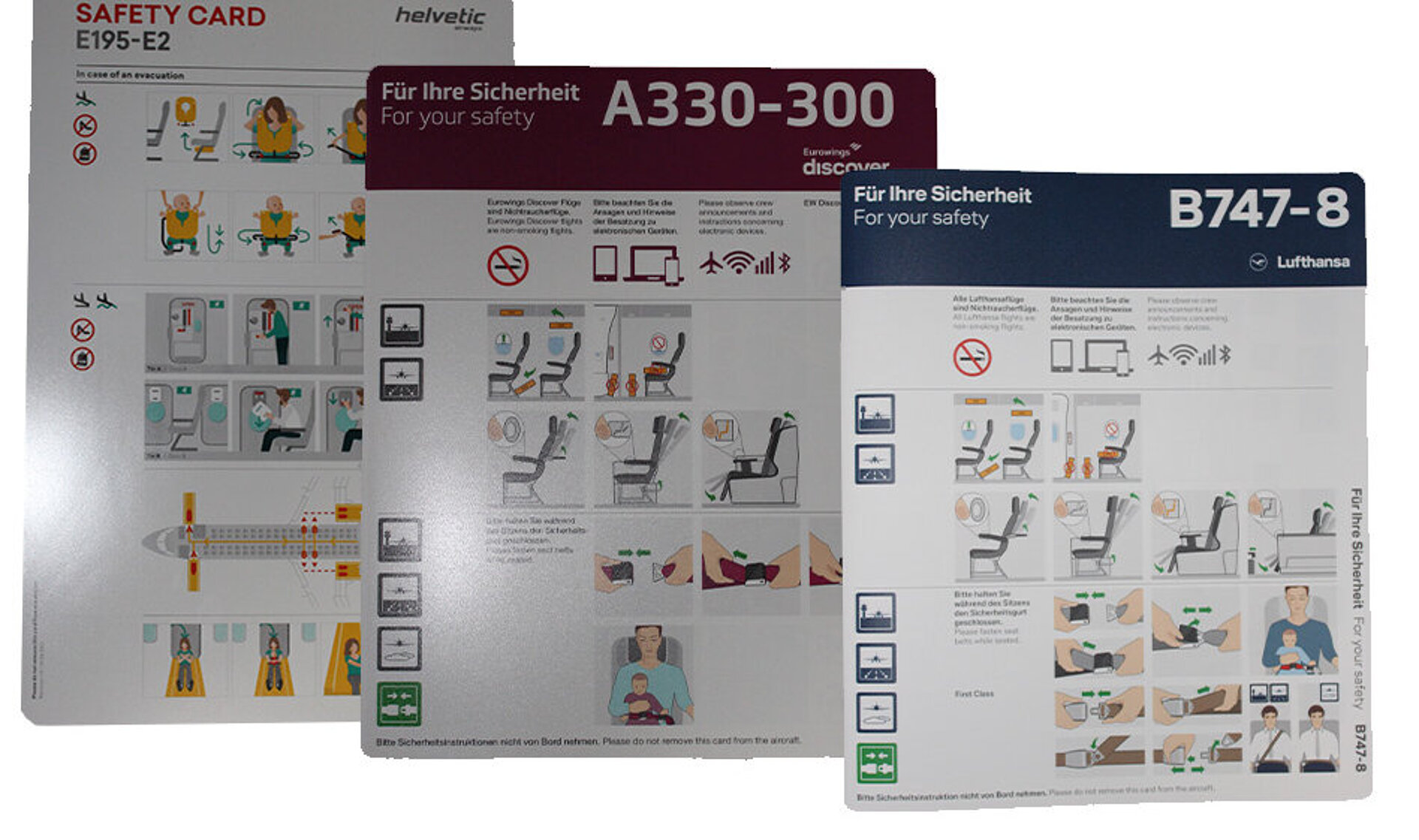

A product that probably all of us have held in our hands at some point: safety or instruction cards in aeroplanes on the way to a holiday. This Lufthansa AG safety card was also printed using IST-UV technology.

The cards are printed on a Heidelberg Speedmaster CX 102 with 5 colours and UV drive in UV offset. The cards are printed in 4/4 colours (Euroscale) and with a semi-matt UV varnish over the entire surface. Printing is done on polypropylene in white with a thickness of 0.3 mm.

Multifunctional packaging that is also fully recyclable. In addition to presenting the bottle at the POS or at the customer's table, the outer packaging also serves as an integrated cooling system that can be filled with ice.

The finished cardboard and the cooler insert were produced using UV offset printing. The recyclable and compostable barrier cardboard was also coated with a special waterproof barrier varnish.

For the outside, after colour printing and partially applied matt varnish and soft-touch effect varnish, high-gloss screen printing was partially overprinted using UV.

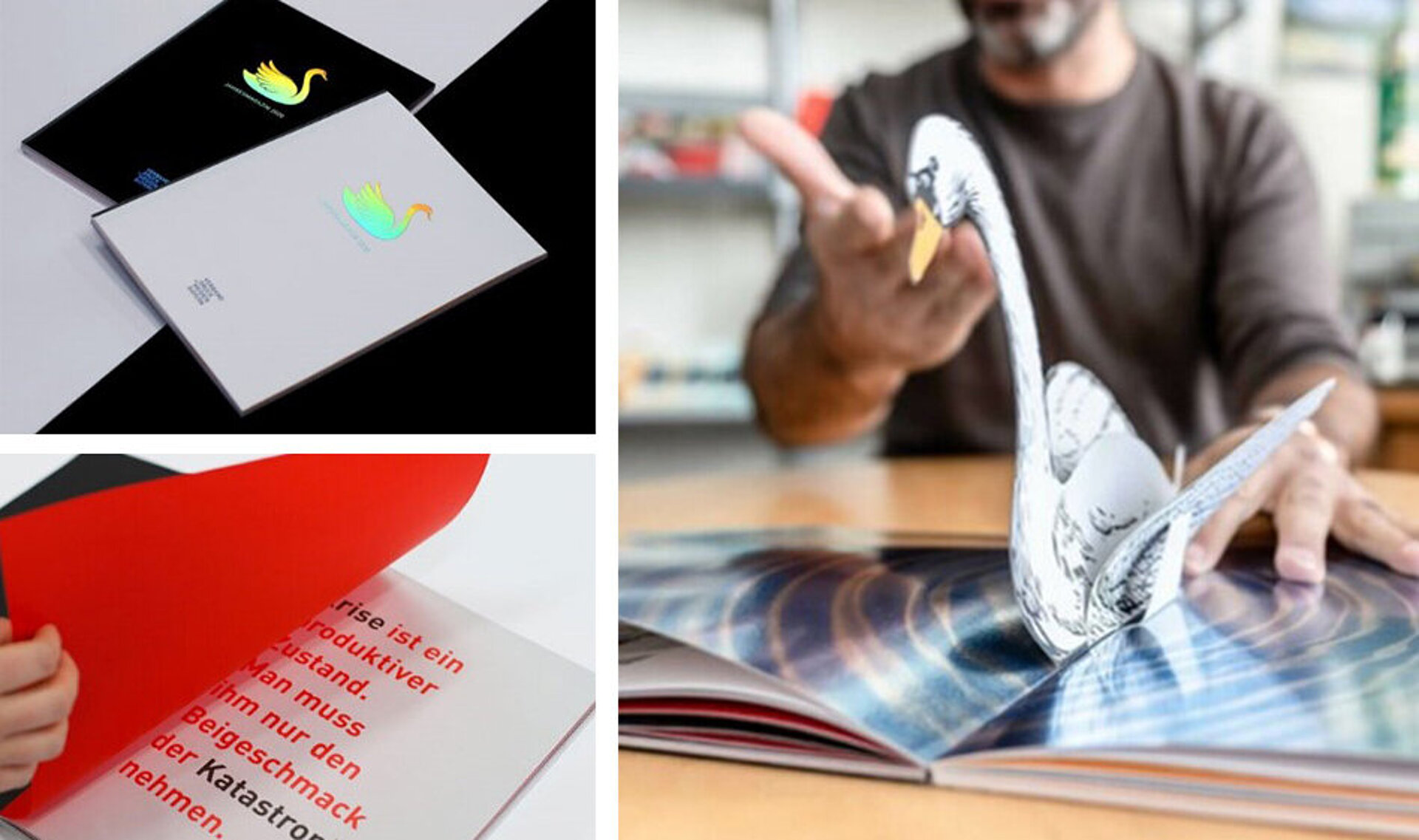

An annual report that is unrivalled: Silver holographic hot foil stamping was used on the two title pages. In the black section, cellophane-wrapped paper was printed with opaque white and black on two sides using mirror foil. This creates a black-metallic effect with silver text. The highlight for the reader is a pop-up swan in the centre of the magazine, which is reflected in the water on two pages with printed mirror foil.

The print was realised with LED UV offset. This allowed opaque white to be used and silver foil to be printed without any problems. Up to six layers of opaque white were used for coloured or black paper.

The elaborately produced reversible booklet with open two-colour thread binding impresses with its fine Gmund paper and sophisticated printing techniques. The portraits of the Starkmacher were first printed in black before being cellophane-wrapped and then overprinted with silver colour to create an impressive 3D effect.

The magazine was finished with blind embossing on the cover, several effect die-cuts, a unique two-tone colour cut and an elaborately designed functional puzzle in the middle of the magazine.

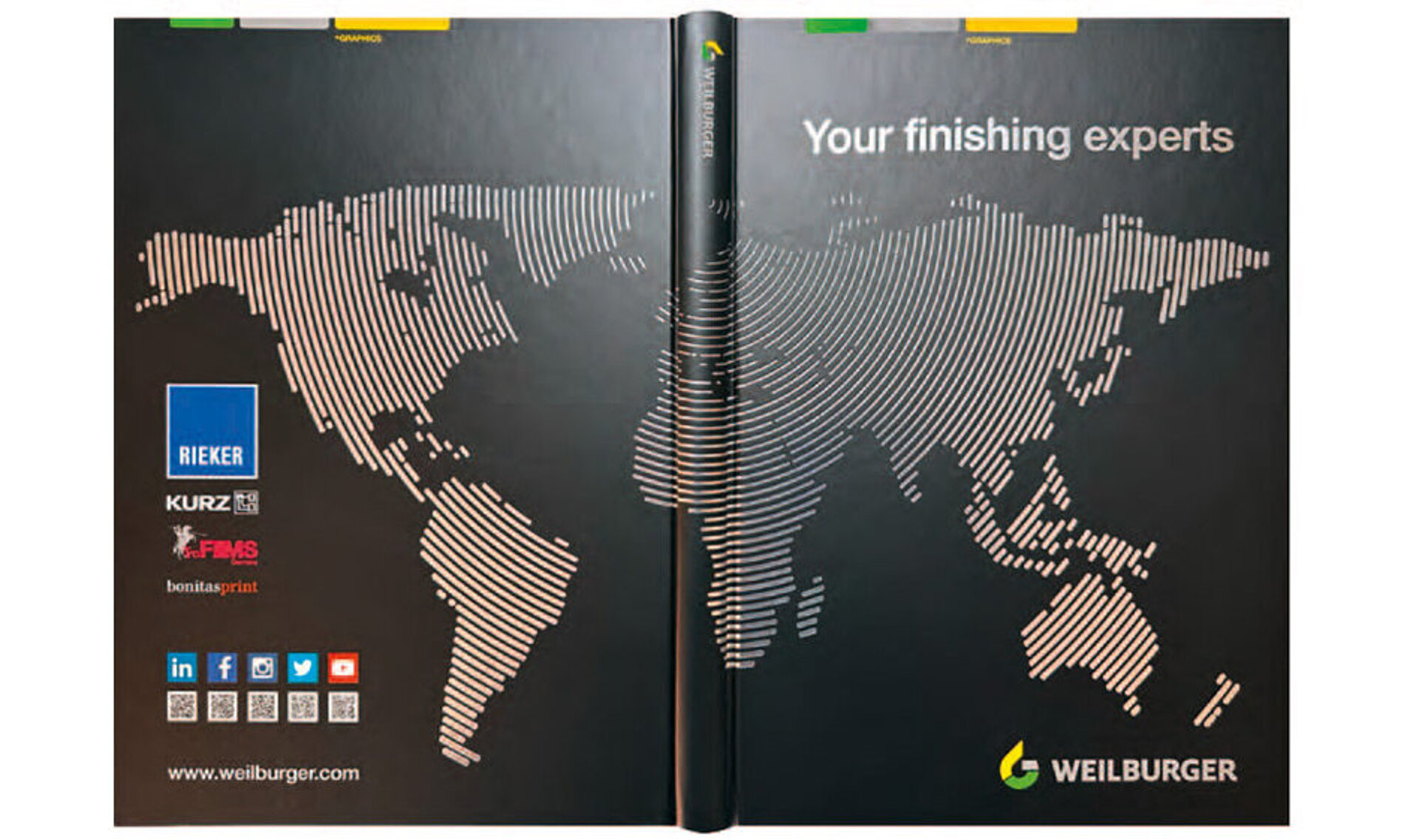

The design is to be deliberately chosen as a noble black with corporate design elements of the company and the distinctive and established world map, in line with the Sample Box project. This world map as well as the headline of the book are to be implemented in a hot transfer process in silver with an ALUFIN® MSU from KURZ directly after print production. Only then, for protection and as a tactile effect, a scratch-resistant matt laminate (TroPROTECT-X from TroFilms GmbH) is to be applied over the entire print sheet using wet transfer and SENOBOND® WB FP FILM LAMINATING ADHESIVE 90L 1000. The resulting highly matt silver of the ALUFIN® is then to be overcoated by screen printing using SENOSCREEN® UV GLOSS LACQUER CATIONIC 82S 4210 and thus restored to a high gloss. Further Corporate Design elements for a homogeneous matt/gloss effect as well as the QR codes for better readability for the cameras of the smartphones are partially overpainted with this coating. As an additional effect, the SENOSCREEN® UV RELIEF GLOSS LACQUER 82S 7220 is then used to bring the WEILBURGER logo on the front cover to the fore both visually and tactilely.

Sample nature

This sample shows an oak multi-layer parquet in the colour natural oiled. The sample has an unbrushed structure.

Sample walnut

This sample shows an oak multi-layer parquet in the colour walnut. The pattern has a brushed texture.

For the presentation of the extensive product catalog of WEILBURGER Graphics GmbH, a sample case including inlay is produced in direct corrugated printing, which can hold 24 refined folding boxes (offset) and a 64-page screen-printed booklet, which is also newly published. This tutorial describes the production of the case and inlay using corrugated direct printing. There are 24 short tutorials available separately for the 24 folding boxes. The technical specifications for the individual effects of the screen-printed booklet can be found on the respective back pages in the booklet itself.

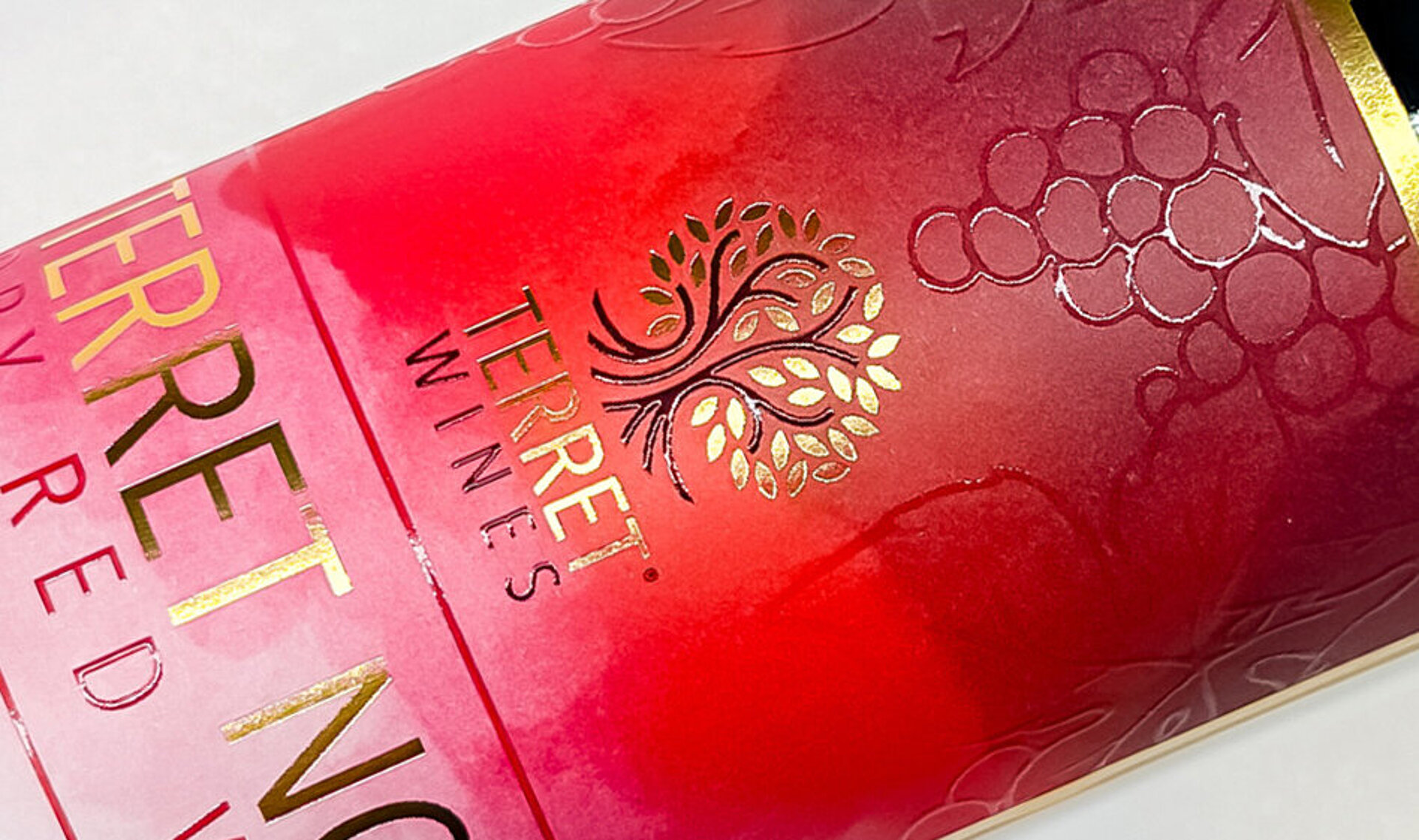

In order to demonstrate the possible applications of the SENOSCREEN® UV RELIEF GLOSS LACQUER FOR UNCOATED PAPER 82R 3811 in combination with uncoated self-adhesive label substrates and a metalized hot transfer application in narrow web offset printing, an self-adhesive wine label is produced together with CCL at the Trittenheim plant.

The aim of this sample production is to create a strong visual as well as tactile contrast through the targeted interaction of the natural substrate surface, the hot embossing and the tactile relief coating.

In order to demonstrate the possible applications of the SENOSCREEN® UV RELIEF EFFECT LACQUER TEXTURED SAND 22R 7810in combination with gloss-coated self-adhesive label substrates and a metalized hot transfer application in narrow-web offset printing, an SK wine label is being produced together with CCL at the Trittenheim plant.

The aim of this sample production is to create a strong visual as well as tactile contrast through the targeted interplay of UV gloss lacquer, hot embossing and tactile sand textured lacquer.