IST METZ has once again made it onto WirtschaftsWoche's list of the ‘500 secret world market leaders 2025’

SMARTcure technology from IST METZ is revolutionising the UV drying process: AI is used to identify potential energy savings and extend the service life of LEDs. The goal: modern, environmentally friendly work processes. Precise power settings for each dryer ensure efficient use of energy.

drupa 2024, the most important industry trade fair for us, came to a successful close on 7 June. Buoyed by the overall upswing of the trade fair, IST was also able to return home with a more than satisfactory final result. Our 50 colleagues worked hard to achieve this and diligently presented our latest innovations and a contemporary company image to the more than 8,000 visitors to our stand, which covered more than 400 m².

For the fifth time in a row, IST METZ has been recognised as "World Market Leader" in the field of UV curing.

This year, the current global challenges led to a selection in the current ranking of world market leaders. Companies like IST METZ are setting standards right now, inspiring others and significantly influencing the development of their industry, according to the Wirtschaftswoche evaluation.

After more than 20 years, IST INTECH moves to new business premises.

As the centrepiece of the new UV Technology Campus, a state-of-the-art research laboratory was built at our headquarters in Nürtingen in 2023. The campus combines application, process and product evaluation in one place. The aim of the investment in research is to make the already sustainable LED UV technology even more efficient and to make LED UV attractive for a wide range of applications. Thus, a team of technology experts is researching the next LED generation in the new competence centre.

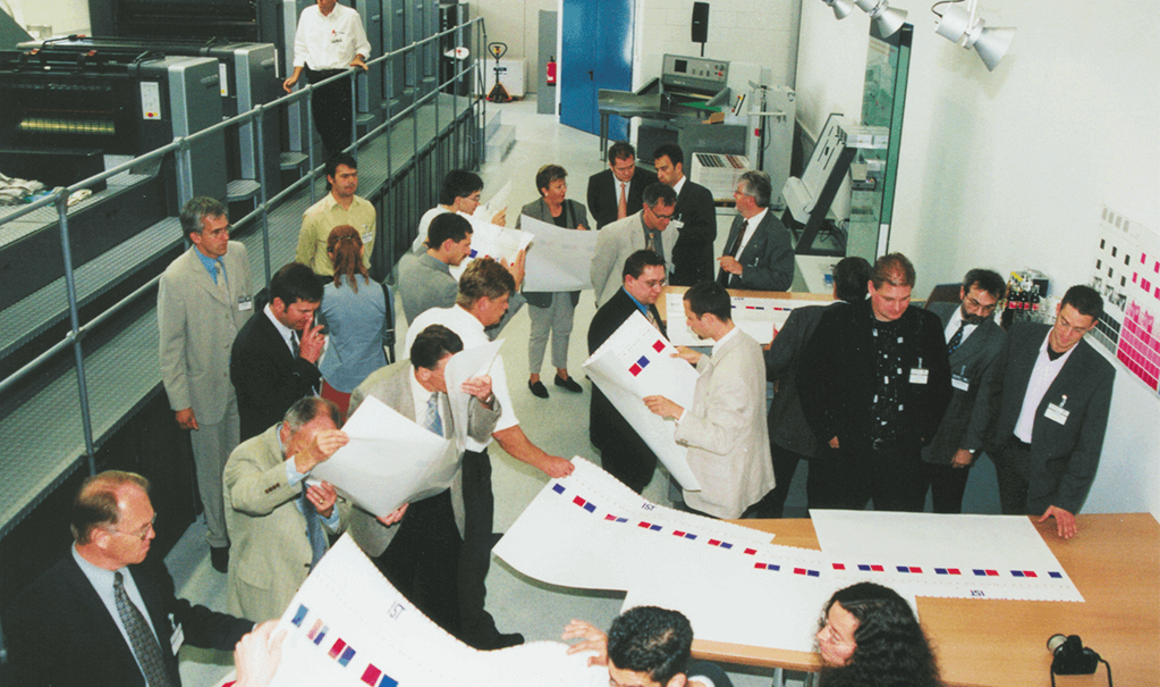

At the UV Days, which took place from July 4 to 6 in Nürtingen, we welcomed around 1,000 guests and 40 exhibitors from a total of 32 countries.

Since January 2022, Christian-Marius Metz and Tim Sterbak jointly steered the fortunes of the UV specialist. With effect from January 1, 2023, Tim Sterbak has been the sole managing director of IST METZ GmbH & CO KG. Christian-Marius Metz will in future focus on his work in the holding company.

IST METZ was included in the list of "The 500 Secret World Market Leaders 2023" by the University of St. Gallen and Wirtschaftswoche.

IST Metz GmbH has made the leap to the top at the 26th edition of the TOP 100 innovation competition and impressed with its innovation climate and innovation successs in the independent selection process.

The UV-based consolidation of glass fibre plastics as an inline production process is an elegant and fast solution. IST METZ was awarded the ThinKing for this sustainable process variant. The State Agency for Lightweight Construction Baden-Württemberg will present this innovation with its ThinKing in March 2022. Every month, Leichtbau BW GmbH uses this label to give a platform to innovative products or services in lightweight construction from Baden-Württemberg.

IST METZ focuses on sustainable growth and realignment. IST Metz has been operating under the name of GmbH und Co. KG since 1 January 2022. The stronger focus on technological development is now also reflected in the reorganisation of the management of IST METZ GmbH & Co. KG. Christian-Marius Metz, grandson of the late company founder Gerhard Metz, has been on the management board since 2015. This is now complemented by Tim Sterbak, who is responsible for the areas of sales and technology.

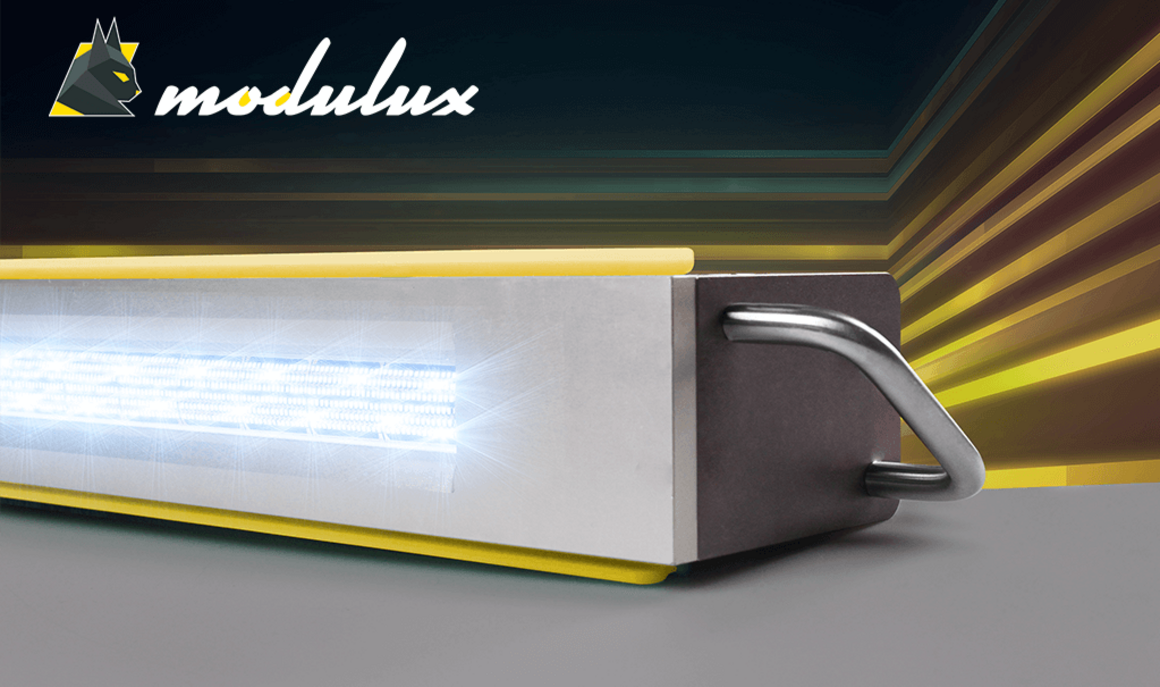

In the growing LED technology market, the new start-up brand modulux specialises in systems for narrow-web flexographic printing. The brand represents straightforward, robust and modular LED solutions, while appealing to a new type of “connected customer” who is used to products being available anytime and anywhere. The young brand operates as an off-shoot of IST Metz and works with the Nürtingen-based UV provider for services that go beyond the sale of UV LED systems, such as installation or maintenance. This collaboration ensures that product performance and additional services are of extremely high quality compared to the market standard, and that the specifications of the machine manufacturer and employers' liability insurance association are fulfilled.

The leading specialist in professional UV-C air disinfection Virobuster® has developed its first joint product range with IST Metz, world market leader for UV systems for surface treatment. Together, competences can bundled, expand the respective product ranges and provide sustainable answers to the handling of aerosols and related requirements with completely new, future-oriented solutions.

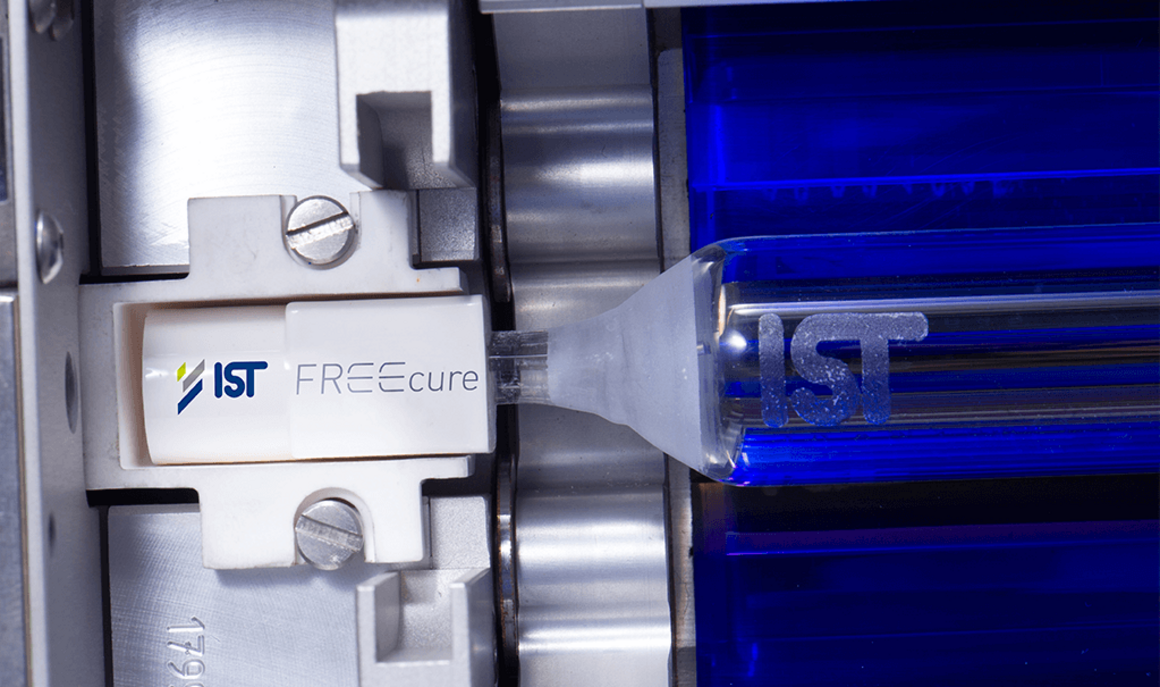

The new FREEcure UV system, developed by IST METZ GmbH together with BASF SE, represents a new kind of cross-linking technology. The shared patent resulting from the collaboration follows the approach of increasing the UVC percentage in the spectrum of a UV lamp. FREEcure is a revolutionary technology that achieves outstanding results without photo initiators, Inertisation and electron beams

With the packaging concept X-Press-U and the Print-Gimmick PadBook, IST Metz wins the German Design Award 2020 twice in the categories Packaging and Print campaign. Both print products were developed and produced in-house on the occasion of the in-house UV Days exhibition.

IST Metz GmbH has made the leap to the top at the 26th edition of the TOP 100 innovation competition and impressed with its innovation climate and innovation successs in the independent selection process.

On the ninth UV Days IST Metz was pleasured to welcome 55 exhibitors and more than 1300 visitors from 46 countries. The UV Days were more well-attended and more diversified than ever before in terms of application technology.

A ranking by the University of St. Gallen has established IST METZ as the world market leader in the field of "UV curing systems based on ultraviolet light, infrared and warm air" for the mechanical and plant engineering industry.

For the second time, the business magazine Capital has honored Germany’s best trainers. Out of 700 companies, 154 were honoured as "Germany's best trainers". With 18 points, IST Metz is one of the companies to receive the award and obtains 4 out of 5 stars on the rating scale.

The paper guitar printed and refined by IST Metz was awarded the Special Mention of the German Design Award 2019 in the category “Integrated Campaigns and Advertising” by the international jury of the German Design Council. The guitar was specially UV-printed and refined by IST Metz.

On the eighth UV DAYS IST METZ was pleasured to welcome 45 exhibitors and 920 visitors from 33 countries. IST METZ thus broke its own records from previous years.

More than 500 employees are working for IST METZ world-wide.

Christian-Marius Metz, grandson of deceased company founder Gerhard Metz and previous Head of the Central Area Operations & Services, was appointed Chief Executive Officer.

The acquisition of the majority interest in the British UV systems manufacturer Integration Technology Ltd. brings an additional gain in expertise in the field of LED UV systems. The IST METZ Group now offers the largest portfolio of UV systems in the world.

IST METZ GmbH created a strategic alliance with the English company Integration Technology Ltd (ITL).

Following successful events in 2002 and 2005 IST METZ has just held its third "UV DAYS" at its Group headquarters in Nürtingen. The UV manufacturer welcomed a total of 697 visitors during the five-day event.

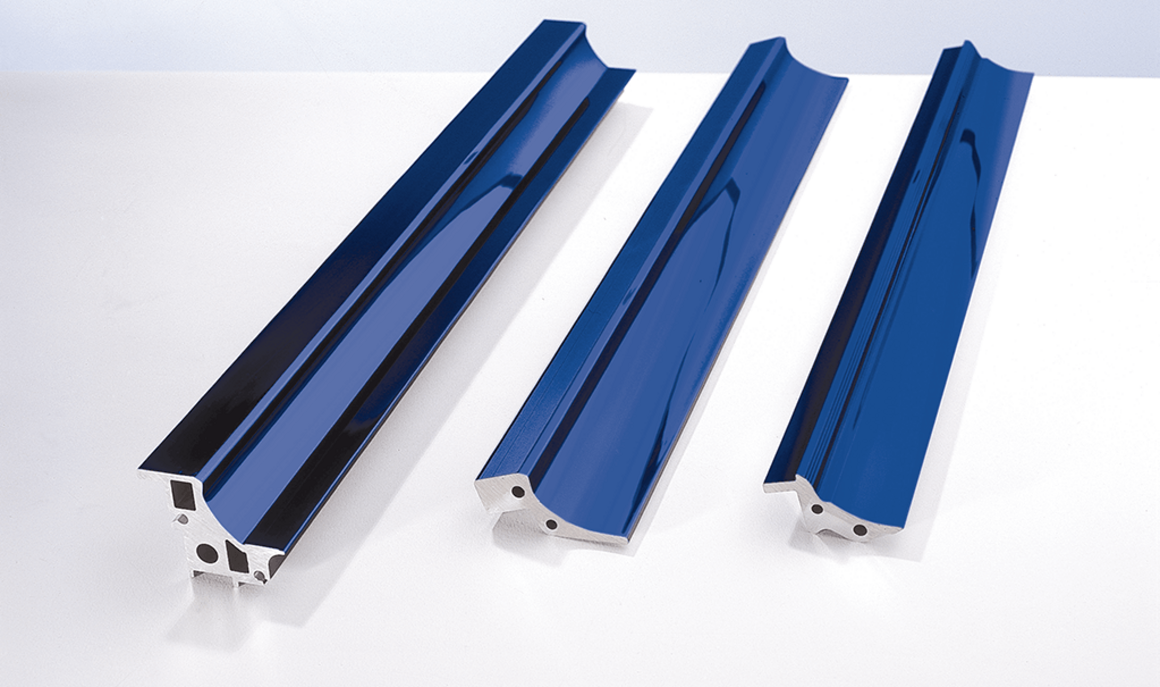

Our increasing independence from suppliers continues with the establishment of S1 Optics GmbH, which sees the manufacture of important reflectors and mirrors for IST UV systems now remain in-house.

The second UV DAYS takes place and interest from the public is even greater this time. The tent erected for the in-house trade fair is used again for further celebrations: The opening of the new building and the launch of the new printing press, as well as the 70th birthdays of Gerhard and Renate Metz. A move is made to tap into the Scandinavian market with the founding of IST Nordic in Sweden.

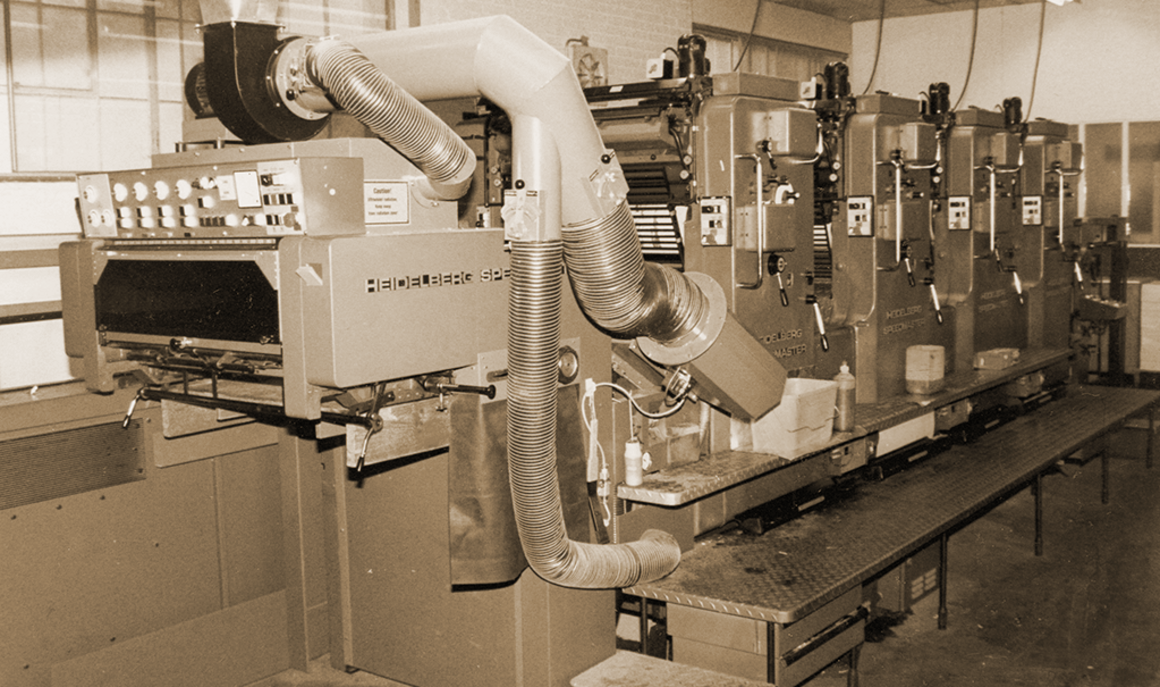

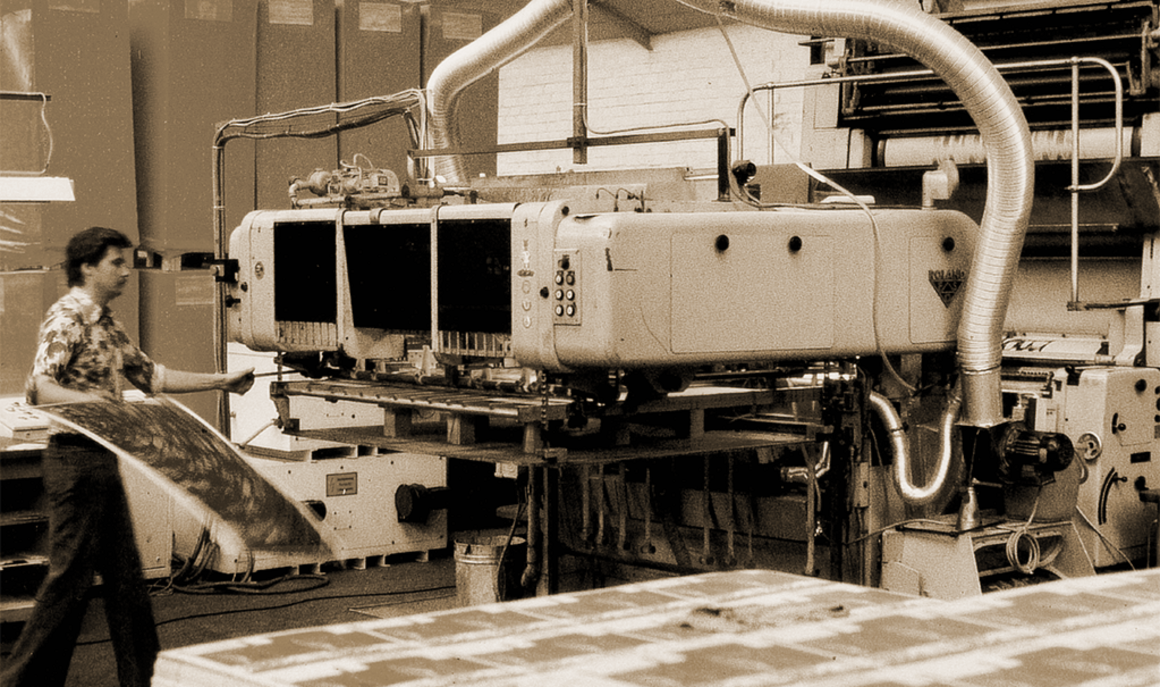

We need another new building: “Building 2004” awaits, complete with new restaurant. At drupa, the company is represented at two stands, showcasing both IST technology and the possibilities presented by the UV Transfer Center. During this time, Zizishausen also receives a new Heidelberg CD 102 7L printing press. The Iberian Peninsula is chosen as the location for the new subsidiary IST Iberica and production of the 100,000th eta lamp marks a further milestone in the company’s success.

A majority stake in VTD Vakuumtechnik Dresden GmbH is acquired and thus a niche in the market for the manufacture of coating systems. At the same time, IST METZ braves the Chinese market for the first time with the opening of a Representative Office in Shanghai.

UV DAYS celebrates its premiere: The in-house trade fair with partners from the printing and chemicals industry proves to be a magnet for customers and visitors. With the founding and construction

of the UV Transfer Center with a Heidelberg CD 102, IST METZ makes considerable investments in facilitating extensive practical trials and the demonstration of UV technology for interested

parties. The 20-year anniversary of the company is marked with fireworks and the variety boasted by IST METZ as a system supplier with the slogan “more than UV”. The IST employees are

also able to contribute to their company financially from 2002 onwards: Mitarbeiterbeteiligungsgesellschaft (“employee involvement”) is set up and offers, in addition to annual dividends, attractive gains on the shares subscribed.

drupa 2000 brings just as much attention to the company as the presentation of the “Enterprise Medal” to Gerhard Metz: State Minister for Economic Affairs Walter Döring presents the medal to the company founder in recognition of his services to the state economy. Moving into “Building ’99” and the 65th birthday of Gerhard and Renate Metz are also cause for celebration. IST Benelux is founded, while there is a reorganisation at the parent company. The product lines pilot project proves to be a success and is now implemented in all areas of IST METZ.

We were running out of space again: “Building ’99” rose from the neighbouring grounds of the recently acquired and demolished building of a bakery business. The staff of almost 300 employees need to be settled in and the steady stream of orders processed. The first UV seminar in collaboration with Heidelberg Druckmaschinen takes place in Wiesloch.

The decision was made to re-name IST® Strahlentechnik metz gmbh in IST METZ GmbH. A new corporate identity was created and with it a standardised corporate design and a new company logo. In order to live up to the expectations of the customers and market in general a pilot project “Product Line MKG” was started. The workshop, design department and sales office were pooled together, which was to prove ground-breaking for the future.

We are met with major change once again: Time to move into “Building ’97”. This same year, gerhard metz metallbau gmbh relocates from Kirchheim to Zizishausen. There are also further reasons for celebration: 30 years of radiation curing and the 50th birthday of Managing Director Joachim Jung are marked with gifts and festivities. This year also sees a restructuring of the IST group: A majority of shares from the company IST® Strahlentechnik metz gmbh are incorporated into the Gerhard and Renate Metz Foundation. This foundation is a subsidiary of the METZ HOLDING, which presides over nine companies with an annual group revenue of approx. 75 million DM.

The company continues to grow: In addition to the founding of subsidiary IST Italia, a new product also adds some wind to our sails. A BLK drying system without any elaborate exhaust-air system is installed for the first time in a Drent Vision printing press. At the same time, the company once again proves itself capable of successfully mastering unusual orders. The Canadian flooring manufacturer Domco receives a UV drying unit with four metres of web width. It was the first inert system, i.e. under low-oxygen conditions. For the employees of IST, a profit-sharing model is introduced.

Change at the top: Gerhard and Renate Metz decide to take a step back, move to Tegernsee in Bavaria and hand over the reins of IST® Strahlentechnik metz gmbh to Peter Zylka and the long-standing Head of Technical Services and Managing Director Joachim Jung. Zylka Consulting GmbH is dissolved and its Sales department incorporated into IST® Strahlentechnik metz gmbh.

Ten years of IST® Strahlentechnik metz gmbh – another reason to celebrate! The media takes an interest in the rapidly developing company history, further established that same year with the founding of a new international subsidiary: IST America.

Our participation in the Ligna event in 1991 in Hanover, one of the most important part of the IST portfolio, the area of wood processing, was supposed to be the last. Wood treatment had become a noticeably less important part of the IST METZ portfolio over the past few years and it was the graphics industry that was really packing the order books. With the purchase of supplier Hantke & Huber in Kirchheim, later to become gerhard metz metallbau gmbh (gmm), there was a boost to company quality and know-how. The first Managing Directors of this subsidiary were Udo Hartrampf and Renate Metz.

More orders follow the drupa exhibition in 1990 and more space from the move to “Building ’89”. In order to keep pace with the company’s strategic and administrative growth, the Advisory Council is set up – a permanent committee of external specialists on hand to assist the Board of Management. This committee continues today in the Gerhard und Renate Metz Foundation.

The first eta lamp is produced – an important step towards security of supply and a standard of quality. Construction work continues in the meantime: Work on “Building ’89” starts and and the topping-out ceremony is a big affair.

The need for more space is growing, and the result of this is to move the IST Sales department for the graphics sector to its own new building, called the “Zylka Building”. It is named after Head of Sales Peter Zylka and his company Zylka Consulting GmbH. The State Minister for Economic Affairs, Martin Herzog, takes an interest in IST at Hannover Messe, while IST turns its attention towards gaining more independence from suppliers. What results is eta plus electronic gmbh & co. kg, set up for the production of UV lamps. IST UK is also established around this time.

The minicure business is going well and taps into a new sector with small drying systems. At the same time, business in Great Britain goes from strength to strength with a large project for the company Field in Bradford. Here, initial contact is made with Andrew Stott who goes on to become one of the co-founders of IST UK a year later.

Our first time at drupa highlights the new focus of IST on the printing industry and a new Works Council on the rapidly expanding growth in personnel. Workshop Supervisor Heinrich Huber is elected senior Chairman of this committee.

The orders are rolling in and work space is getting cramped. It is thus time for our own company building in Zizishausen, known as “Building ’85”. Its unusually bevelled shape results from attempts to accommodate the pipeline of the Lake Constance Water Supply.

New orders bring with them a wealth of new experience: In the Soviet Union, a 3D chair varnishing system is equipped with a UV drying unit from the plant in Wolfschlugen. The intention is to produce 600,000 chairs each year using this system.

An IST drying system is installed on a Heidelberg Speedmaster printing press for the first time. Around this time, the company establishes its footing on the international stage with the founding of the subsidiary IST France. The company now employs 30 people.

An opportunity arises from the downfall of Hildebrand – and it is grabbed with both hands: Gerhard and Renate Metz take over all shares of Werner & Pfleiderer Hildebrand Strahlentechnik GmbH as the Hildebrand company declares itself insolvent. At the same time, the decision is taken to distance the business from the less than profitable electron beam technology with a change of name: The company is now called “IST® strahlentechnik gmbh” and relocates to Wolfschlugen, together with 20 employees from the Hildebrand headquarters in Oberboihingen.

Gerhard Metz elected to the Executive Board of the “Verband Deutscher Maschinen- und Anlagenbau” (VDMA), Surface Technology. As radiation technicians, we built an ESTRA laboratory and demonstration system – also known as “Schulzy”. This was also used for the Beiersdorf tests (behind the brand Nivea, among others). This led to the first order for a production plant at Beiersdorf.

The first UV installation of a MAN-Ultra printing press takes place. Werner & Pfleiderer Hildebrand Strahlentechnik GmbH is represented for the first time at Interpack in Stuttgart.

The company Werner & Pfleiderer Hildebrand Strahlentechnik GmbH is founded in Oberboihingen. Gerhard Metz holds the position of Managing Director at this stage, previously the Head of Technical Services in the Development department at Hildebrand GmbH. In collaboration with Stuttgart’s Werner & Pfleiderer, there is to be a further promotion of electron beams and UV radiation drying. The first appearance as an independent company at what was then the most important industry trade fair in Leipzig further strengthens already existing contacts in the former Eastern Bloc.

The first big order for the new IST technology, valued at 67 million DM, comes from the USSR. The “Iwanowo”, with 17 filling- and varnishing lines, 16 of which have UV filling and IRL top coat dryers. 20 new designers and 50 additional engineers are brought on board for the processing of the order, which is then launched early in 1974. Iwanowo was a risk, a matter of prestige and also a learning curve.

The name “IST” also first appears, which stands for “Impuls-Strahlungs-Trocknung” (“Impulse radiation drying”). That same year, a patent application is made for IST technology. The first partners to contribute towards developing this process further come from the varnish industry.

There are initial indications from the varnishing industry that varnishes display curing properties when exposed to fluorescent tubes – the first stage of radiation drying. As Technical Assistant to the Board of Management for the company Hildebrand, Gerhard Metz becomes involved with this topic in 1966 simply by chance. One of the first Hildebrand UV systems then appears in 1969 for the company Triangel – back then a standard product for the timber industry.