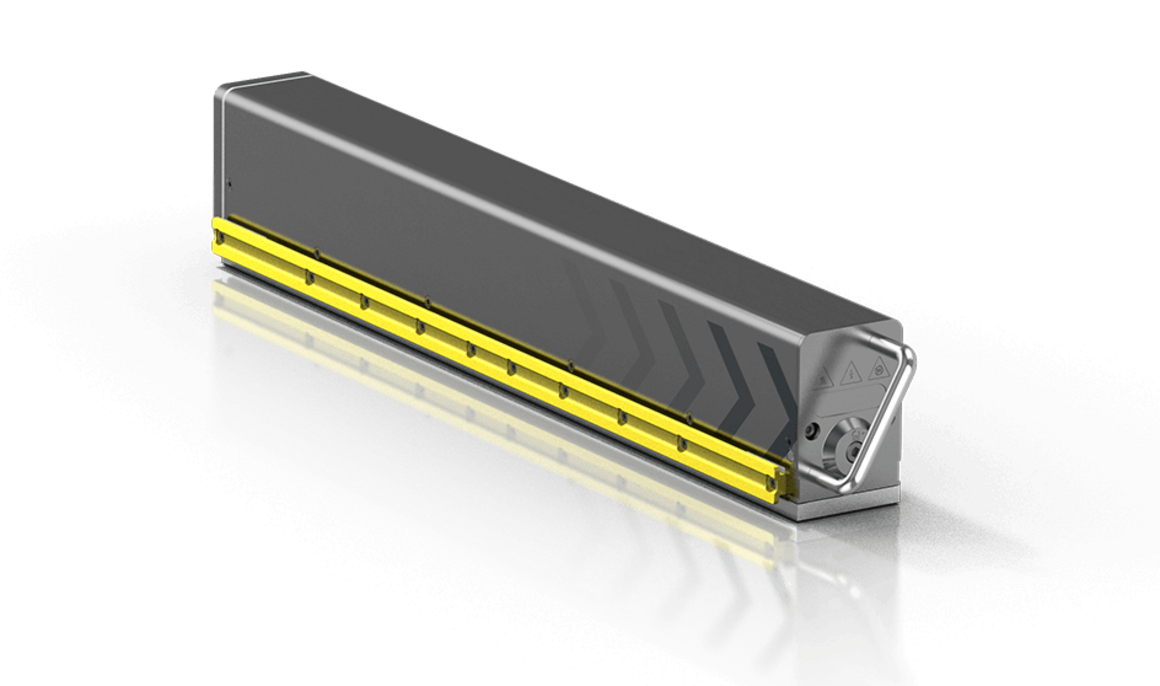

The production friendly concept of the modulux LED curing units allows you to configure your web press according to your requirements. You can choose all the equipment you need to fully configure your web press from our catalogue. Choose either the basic modulux set-up or customise it with additional accessories and components, you can even add the complete technical integration as well as installation services – all at a reasonable price – it's up to you!

modulux systems offer high-precision optics that achieve an exceptionally high UV output on the substrate thanks to specially designed lenses. Thanks to the uniform and continuous spot strip, the peak intensity of the UV spectrum at 395 nm (standard) achieves an increase of between 120 % and 200 % compared to conventional UV lamps.

To maximise the service life of the LEDs, an optimum temperature environment is crucial. Our sophisticated thermal management ensures that the operating temperature is reduced to a minimum. The direct connection of the LEDs to the circuit board, combined with thermally conductive materials and effective water cooling, ensures stable performance and an operating temperature of 15-25 °C. This enables an impressive LED service life of more than 35,000 hours.

With modulux, you only pay for the components and services that you actually need for your machine integration. This means you avoid unnecessary costs for superfluous parts and services that you don't need.

You can upgrade or retrofit almost any machine with our modulux LED systems. Thanks to the modular concept and optional components, we can fulfil your individual requirements. Converting to LED-UV can lead to considerable energy savings - getting started with LED technology is possible with modulux without major costs and often pays for itself after only after 2-3 years. modulux systems can also be combined as hybrid with any other IST light source and can also be equipped with HotSwap technology.

Seamless LED integration after each station

Various labelling substrates are possible: from paper to shrink sleeves to unsupported films to metallic foil or even heat-sensitive materials like synthetics

High speed up to 200 m/min (650 ft/min)