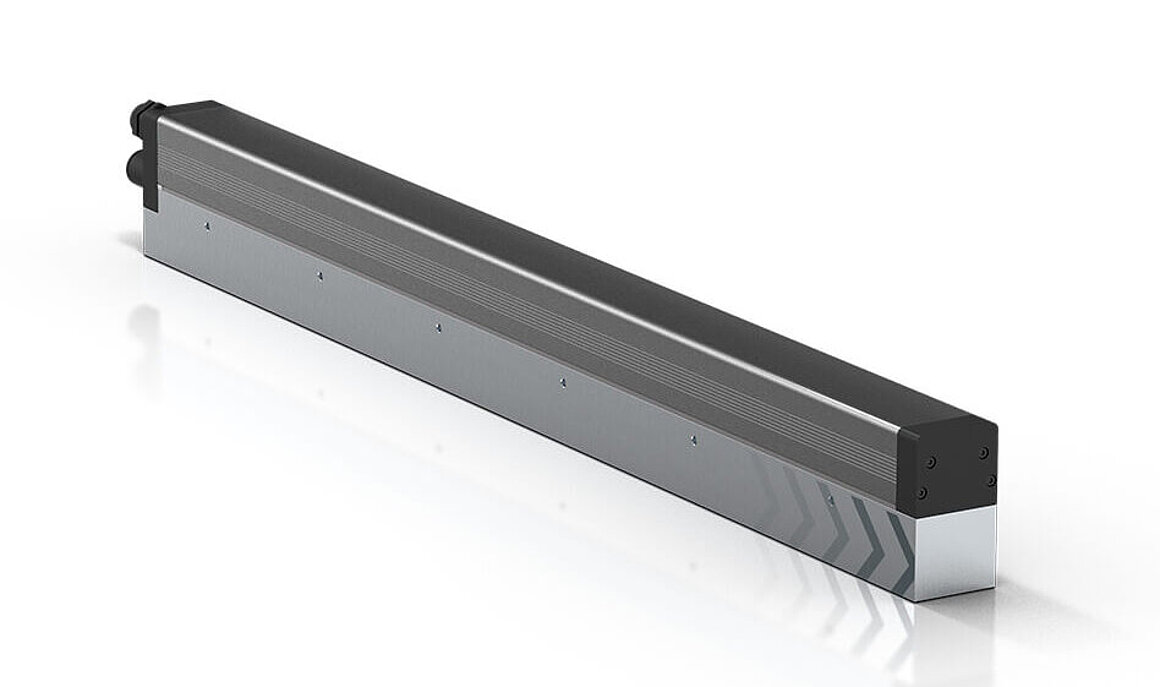

Our innovative system has been specially developed for applications where larger distances are required. Thanks to special optics, it enables optimum performance even with wider installation distances. The high performance of our system makes it ideal for use in areas such as wide-web and sheet-fed offset, where high speeds and precise results are crucial. Each light source is equipped with sensors, including temperature, voltage, current and others, to ensure the optimum operating condition of the system.

Simple integration with the press

For the integration and automatic operation of the LED curing system, only speed, print on and off signals and the necessary safety signals from the printing press are required.